Introduction

HBLT-A2 capacitive liquid level transmitters are used to measure liquid levels in refrigerant vessels. The sensor transmits a current signal from 4 to 20 mA (4 mA when the transmitter does not register liquid - and 20 mA when the entire transmitter is surrounded by liquid).

The difference between the new HBLT-A2 and the HBLT-A1 is the electronic head. We have used the electronic head from our HBLC sensor, which gives more opportunities in the PC tool for configuration with 3 parameters to set up the sensor.

HBLT-A2 has a digital display instead of the bar graph known from HBLT-A1 and HBLT-A2 is an intelligent sensor with a built-in microprocessor. It emits a 4-20 mA signal, which is proportional to the sensor’s set range of measurement. Apart from the 4-20 mA signal the sensor also has a built-in controller. The controller can be set-up with all the parameters necessary for controlling a modulating motor valve. The sensor can be delivered with a cable for direct supply to and control of motor valves.

HBLT-A2 provides new possibilities but has the same price as HBLT-A1.

Technical details

- Digital display

- Controller built inside

- Advanced setting for controlling modulating valve

- 3 parameters to set up the sensor

- Easy diagnostics

- The HBLT-A2 is a perfect solution under turbulent conditions like marine applications

- Split design which makes it possible to make easy installation and diagnostics

The electronic part can be easily disconnected by loosening the threaded nut / union nut - Proven and reliable design with process signal output of 4-20 mA

- Designed for the industrial refrigeration industry - max pressure up to 100 bar & high protection class

Specifications

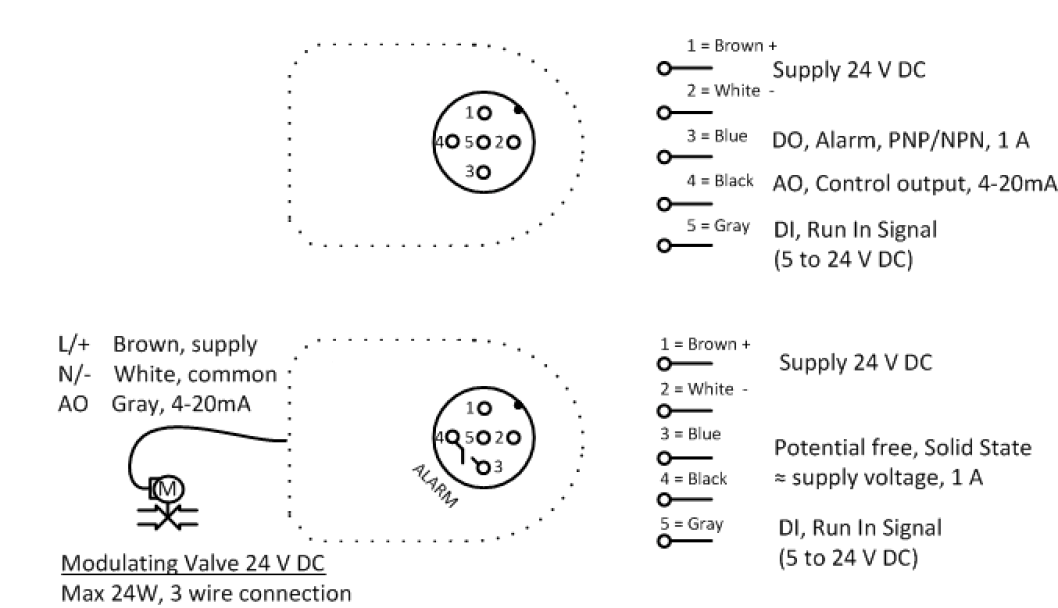

Connection diagram

The sensor can be programmed to either emit a linear signal, which is identical to the tank level, or to regulate a valve for the purpose of obtaining the same level in the tank (float valve).

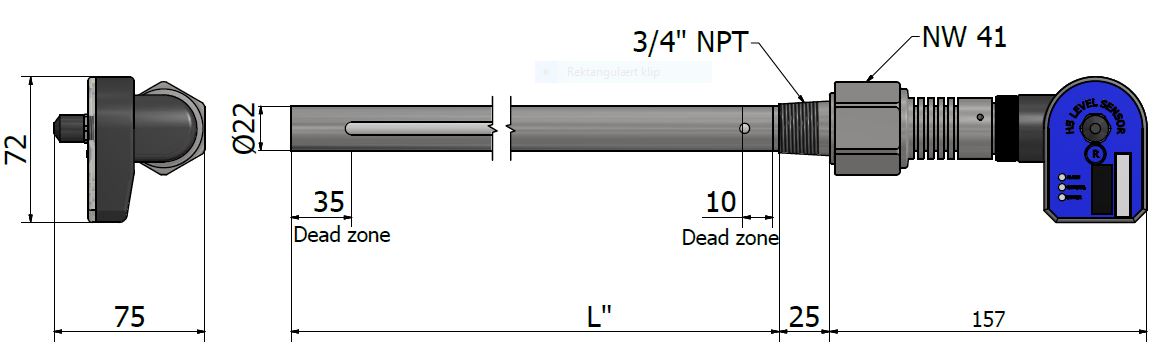

Drawing

| Power supply | |

|---|---|

| Voltage | 24 AC/DC + 10% |

| Plug connection | M12, 5 pins - DIN 0627 |

| Output | |

| Analog output | 4-20 mA |

| Environmental conditions | |

| Ambient temperature | -30...+50°C |

| Refrigerant temperature | -60...+80°C |

| Max. pressure | 100 bar |

| Protection class | IP65 |

| Vibrations | IEC 68-2-6 (4g) |

| Mechanical specifications | |

| Thread connections | 3/4” NPT / BSP |

| Material - mechanical parts | AISI 304 / PTFE |

| Material - electronic parts | Nylon 6 (PA) |

| House type | Angle |

| Approvals | |

| EMC test | EN 61000-2 |

| Indication | |

| LED indication | Green, yellow, and red |

Applications

Use of HBLT-A2

When using a level sensor for measuring Ammonia in a compact plate and shell heat exchanger or other systems with turbulent conditions, we have new recommendation based on recent experience:

For Stand-pipes with stable conditions (smooth changes in the level):

Use a HBLT-Wire or a HBLT-A2 or HBLT-A1 rod-style sensor.

For Stand-pipes with turbulent conditions (a lot of turbulence, cooking, foaming, liquid from the top):

- Use a HBLT-A2 or HBLT-A1 rod-style sensor, or

- Use only a HBLT-Wire sensor when you have it mounted in an inner guide-tube of e.g. DN25 as

illustrated. The guide-tube will dampen the turbulence and the foaming and you will have a good

measurement. - If HBLT-Wire sensor is already mounted under these conditions WITHOUT a guide-tube, do

eventually set the filter time function between 60-120 seconds to dampen the signal from the

turbulent conditions.

For tank/drum installation:

- Use a HBLT-A2 or HBLT-A1 rod-style sensor, or

- Use only a HBLT-Wire sensor when you have it mounted in an inner guide-tube of e.g. DN25 as

illustrated. The guide-tube will dampen the level and the foaming and you will have a good

measurement. - If HBLT-Wire sensor is already mounted under these conditions WITHOUT a guide-tube,

do eventually set the filter time function between 60-120 seconds to dampen the signal from the

turbulent conditions.

For Alpha Laval U-turn evaporator:

- Use a HBLT-A2 or HBLT-A1 rod-style sensor.

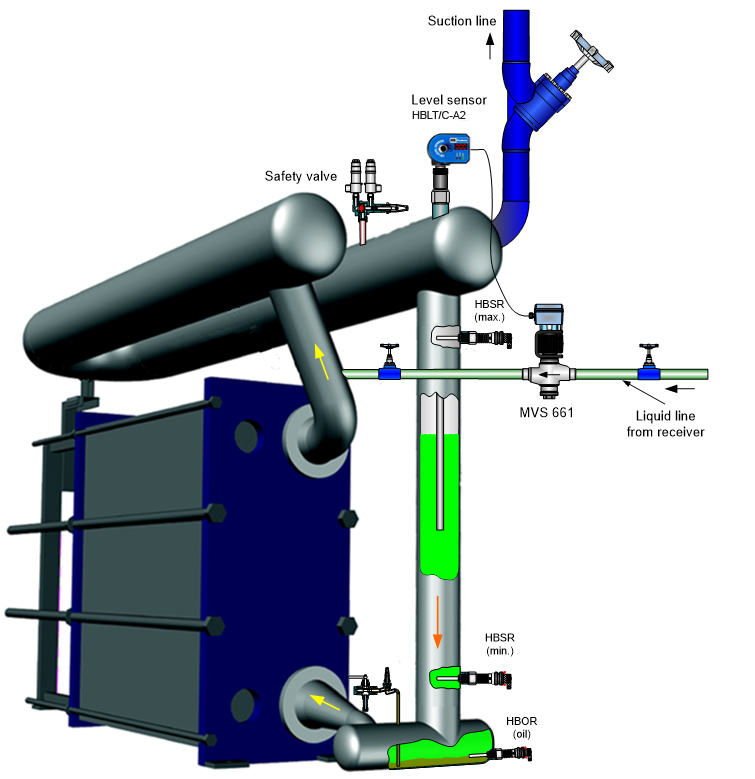

HBLT/C-A2, here’s a cable connection directly to a modulating fluid valve

such as Siemens MVS661, this will save installations cost because there is built

in a level controller in the sensor head.

Disclaimer

| Length / thread | Valve type | Ordering code with LED |

|---|---|---|

| 280 mm / 1" BSP | HBLT-A2-2.8 | |

| 500 mm / 1" BSP | HBLT-A2-5 | |

| 800 mm / 1" BSP | HBLT-A2-8 | |

| 1000 mm / 1" BSP | HBLT-A2-10 | |

| 1200 mm / 1" BSP | HBLT-A2-12 | |

| 1500 mm / 1" BSP | HBLT-A2-15 | |

| 1700 mm / 1" BSP | HBLT-A2-17 | |

| 2200 mm / 1" BSP | HBLT-A2-22 | |

| 3000 mm / 1" BSP | HBLT-A2-30 | |

| 6" / 3/4” NPT | HBLT-A2-6U | |

| 8" / 3/4” NPT | HBLT-A2-8U | |

| 12" / 3/4” NPT | HBLT-A2-12U | |

| 15.3" / 3/4” NPT | HBLT-A2-15.3U | |

| 19.2" / 3/4” NPT | HBLT-A2-19.2U | |

| 23.1" / 3/4” NPT | HBLT-A2-23.1U | |

| 30" / 3/4” NPT | HBLT-A2-30U | |

| 35" / 3/4” NPT | HBLT-A2-35U | |

| 45" / 3/4” NPT | HBLT-A2-45U | |

| 55" / 3/4” NPT | HBLT-A2-55U | |

| 65" / 3/4” NPT | HBLT-A2-65U | |

| 85" / 3/4” NPT | HBLT-A2-85U | |

| 105" / 3/4” NPT | HBLT-A2-105U | |

| 120" / 3/4” NPT | HBLT-A2-120U | |

| Electronic part for HBLT-A2 | HBLT-A2-EL | |

| 280 mm / 1" BSP | Modulating | HBLT/C-A2-2.8 |

| 500 mm / 1" BSP | Modulating | HBLT/C-A2-5 |

| 800 mm / 1" BSP | Modulating | HBLT/C-A2-8 |

| 1000 mm / 1" BSP | Modulating | HBLT/C-A2-10 |

| 1200 mm / 1" BSP | Modulating | HBLT/C-A2-12 |

| 1500 mm / 1" BSP | Modulating | HBLT/C-A2-15 |

| 1700 mm / 1" BSP | Modulating | HBLT/C-A2-17 |

| 2200 mm / 1" BSP | Modulating | HBLT/C-A2-22 |

| 3000 mm / 1" BSP | Modulating | HBLT/C-A2-30 |

| 6" / 3/4” NPT | Modulating | HBLT/C-A2-6U |

| 8" / 3/4” NPT | Modulating | HBLT/C-A2-8U |

| 12" / 3/4” NPT | Modulating | HBLT/C-A2-12U |

| 15.3" / 3/4” NPT | Modulating | HBLT/C-A2-15.3U |

| 19.2" / 3/4” NPT | Modulating | HBLT/C-A2-19.2U |

| 23.1" / 3/4” NPT | Modulating | HBLT/C-A2-23.1U |

| 30" / 3/4” NPT | Modulating | HBLT/C-A2-30U |

| 35" / 3/4” NPT | Modulating | HBLT/C-A2-35U |

| 45" / 3/4” NPT | Modulating | HBLT/C-A2-45U |

| 55" / 3/4” NPT | Modulating | HBLT/C-A2-55U |

| 65" / 3/4” NPT | Modulating | HBLT/C-A2-65U |

| 85" / 3/4” NPT | Modulating | HBLT/C-A2-85U |

| 105" / 3/4” NPT | Modulating | HBLT/C-A2-105U |

| 120" / 3/4” NPT | Modulating | HBLT/C-A2-120U |

| Electronic part for HBLT/C-A2 | Modulating | HBLT/C-A2-EL |

| 280 mm / 1" BSP | Stepper | HBLT/S-A2-2.8 |

| 500 mm / 1" BSP | Stepper | HBLT/S-A2-5 |

| 800 mm / 1" BSP | Stepper | HBLT/S-A2-8 |

| 1000 mm / 1" BSP | Stepper | HBLT/S-A2-10 |

| 1200 mm / 1" BSP | Stepper | HBLT/S-A2-12 |

| 1500 mm / 1" BSP | Stepper | HBLT/S-A2-15 |

| 1700 mm / 1" BSP | Stepper | HBLT/S-A2-17 |

| 2200 mm / 1" BSP | Stepper | HBLT/S-A2-22 |

| 6" / 3/4” NPT | Stepper | HBLT/S-A2-6U |

| 8" / 3/4” NPT | Stepper | HBLT/S-A2-8U |

| 12" / 3/4” NPT | Stepper | HBLT/S-A2-12U |

| 15.3" / 3/4” NPT | Stepper | HBLT/S-A2-15.3U |

| 19.2" / 3/4” NPT | Stepper | HBLT/S-A2-19.2U |

| 23.1" / 3/4” NPT | Stepper | HBLT/S-A2-23.1U |

| 30" / 3/4” NPT | Stepper | HBLT/S-A2-30U |

| 35" / 3/4” NPT | Stepper | HBLT/S-A2-35U |

| 45" / 3/4” NPT | Stepper | HBLT/S-A2-45U |

| 55" / 3/4” NPT | Stepper | HBLT/S-A2-55U |

| 65" / 3/4” NPT | Stepper | HBLT/S-A2-65U |

| 85" / 3/4” NPT | Stepper | HBLT/S-A2-85U |

| 105" / 3/4” NPT | Stepper | HBLT/S-A2-105U |

| 120" / 3/4” NPT | Stepper | HBLT/S-A2-120U |

| Electronic part for HBLT/S-A2 | Stepper | HBLT/S-A2-EL |